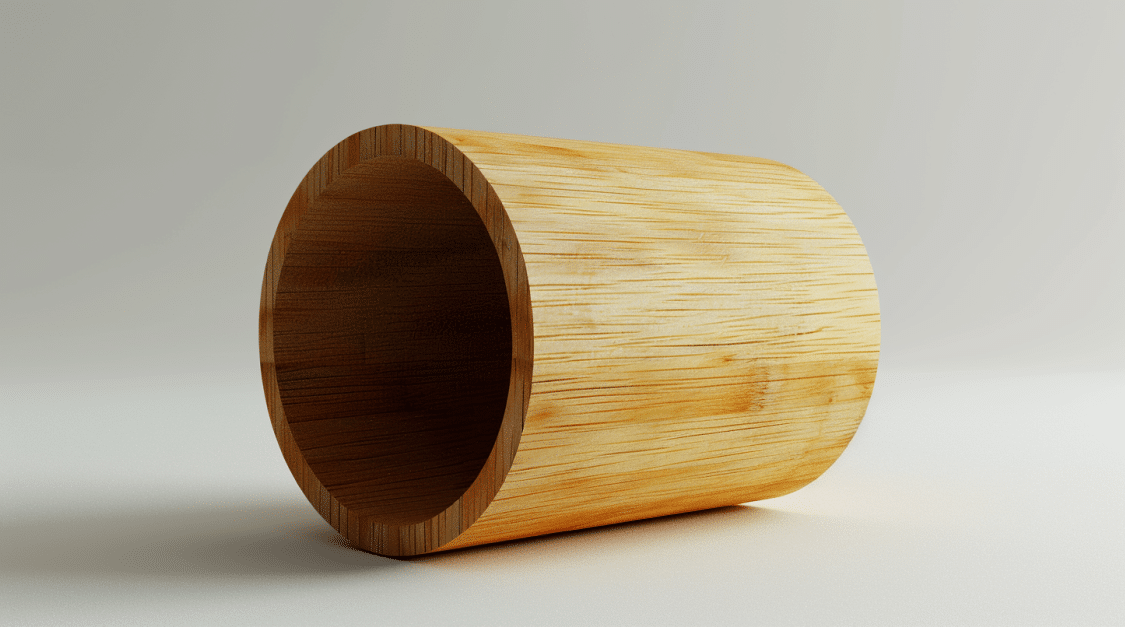

In the realm of geometry, the hollow cylinder stands as one of the most fundamental shapes, characterized by their curved surface and two parallel circular bases. However, within the realm of cylinders lies a lesser-explored variant: the hollow cylinder. This intriguing form presents unique properties and applications that merit closer examination. In this article, we delve into the intricacies of hollow cylinders, uncovering their characteristics, uses, and significance across various fields.

Understanding Hollow Cylinders

Definition and Structure

A hollow cylinder, also known as a tubular structure, is akin to a solid cylinder but with a crucial distinction: it contains empty space within its confines. This space can vary in size, creating a cylindrical shell rather than a solid mass. Visually, it resembles a pipe or a tube, with a circular cross-section and a void at its center.

Geometric Properties

Like solid cylinders, hollow cylinders possess certain geometric properties that define their shape and dimensions. These include the radius of the outer and inner circular bases, the height or length of the cylinder, and the thickness of the walls comprising its hollow structure. Understanding these parameters is essential for accurately describing and analyzing hollow cylinders in mathematical contexts.

Applications of Hollow Cylinders

Engineering and Construction

Hollow cylinders find extensive use in engineering and construction applications. They serve as structural elements in buildings, bridges, and various infrastructure projects. By utilizing materials such as steel, aluminum, or reinforced concrete, engineers can create robust hollow cylinders capable of withstanding significant loads while minimizing material usage and overall weight.

Piping and Tubing

One of the most prevalent applications of hollow cylinders is in piping and tubing systems. Whether conveying fluids, gases, or electrical wiring, cylindrical conduits provide a reliable means of transportation within industrial, residential, and commercial settings. The hollow nature of these cylinders allows for the efficient flow of substances while facilitating easy installation and maintenance.

Manufacturing and Fabrication

In manufacturing processes, hollow cylinders play a vital role in shaping, molding, and forming various products. They serve as molds, dies, and mandrels for shaping materials such as metal, plastic, and glass into desired configurations. Hollow cylinders enable intricate designs and precise dimensions, making them indispensable in industries ranging from automotive manufacturing to aerospace engineering.

Mathematical Considerations

Volume and Surface Area

Calculating the volume and surface area of a hollow cylinder involves considering both its outer and inner dimensions. The volume is determined by subtracting the volume of the inner cylinder from that of the outer cylinder, while the surface area accounts for both the curved surface and the circular bases. These calculations are essential for engineering and design purposes, providing insights into material requirements and structural integrity.

Moment of Inertia

The moment of inertia, a measure of an object’s resistance to rotational motion, differs between solid and hollow cylinders. Due to the distribution of material around the axis of rotation, hollow cylinders exhibit different moment of inertia values compared to their solid counterparts. Engineers and physicists utilize these values in analyzing the rotational behavior of cylindrical structures and machinery.

Advantages and Considerations

Weight Reduction

One of the primary advantages of hollow cylinders lies in their potential for weight reduction. By hollowing out the interior while maintaining structural integrity, engineers can achieve significant reductions in overall weight without compromising strength or durability. This feature is particularly advantageous in industries where weight savings translate to improved performance and efficiency, such as aerospace and automotive engineering.

Material Efficiency

Hollow cylinders offer superior material efficiency compared to solid counterparts. By utilizing only the necessary material in the outer shell and minimizing excess mass, manufacturers can optimize resource utilization and reduce production costs. This efficiency extends beyond material usage to transportation and assembly processes, contributing to sustainable practices and environmental conservation.

Structural Integrity

While hollow cylinders offer numerous benefits, maintaining structural integrity is paramount. Factors such as wall thickness, material selection, and manufacturing techniques influence the strength and stability of hollow cylindrical structures. Engineers must carefully balance design considerations to ensure that hollow cylinders meet safety standards and performance requirements under various loading conditions.

Conclusion

Hollow cylinders represent a captivating variation of the classic cylindrical shape, offering unique properties and applications across diverse fields. From engineering and construction to mathematics and manufacturing, these structures play a crucial role in shaping our modern world. By understanding the intricacies of hollow cylinders, we can harness their potential to innovate and advance technology in the years to come.

Published by: Nelly Chavez