When you think about it, motors are everywhere, quietly powering the world we live in. From the hum of your refrigerator to the massive engines in industrial machinery, motors are the heartbeat of countless industries. Electric motors, in particular, are essential in sectors like manufacturing, transportation, and even healthcare.

In manufacturing, motors drive the production lines that churn out everything from cars to electronics. In the world of transportation, both electric and hybrid vehicles rely on advanced motors to move us forward efficiently. Healthcare also benefits from motors powering essential equipment like MRI machines and surgical instruments.

The energy sector isn’t left behind, either. Wind turbines, a crucial part of renewable energy, depend on motors converting wind into electrical power. Even your household appliances, like vacuum cleaners and washing machines, owe their functionality to reliable electric motors.

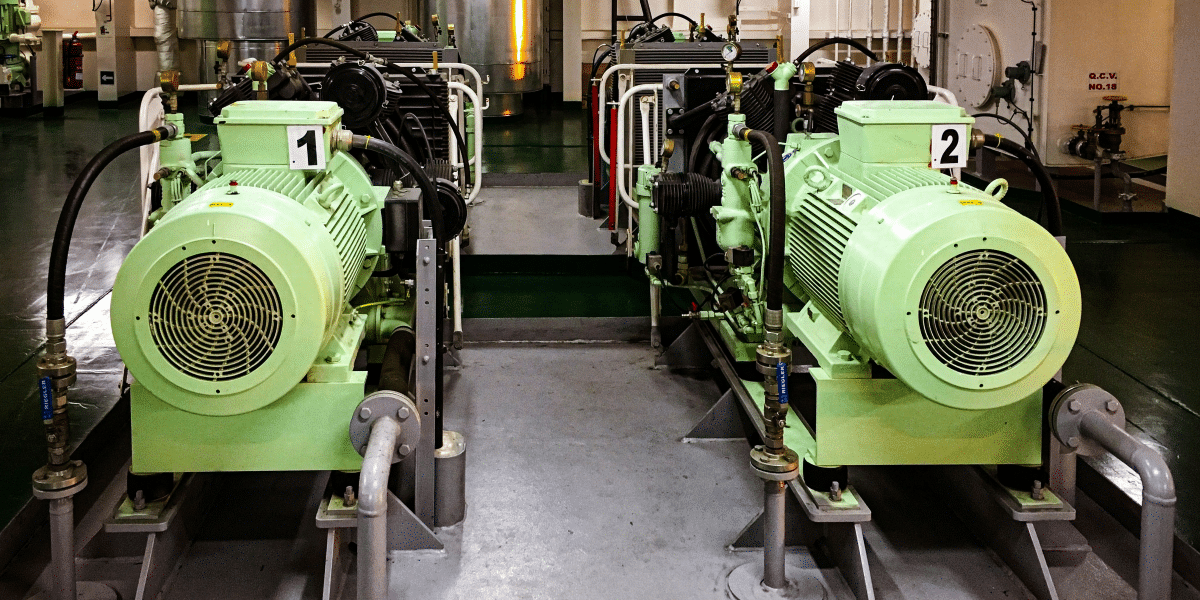

The Role of Motors in Manufacturing and Production

In the world of manufacturing and production, motors are indispensable. They power everything from conveyor systems to sophisticated robotics and precision machine tools, helping to improve efficiency, performance, and overall productivity.

Conveyor Systems and Robotics

Conveyor systems and robotics are the backbone of modern production lines. Motor power conveyor belts allow for the smooth and consistent movement of materials. The efficiency gains here can’t be overstated—reducing manual labor and speeding up processes.

Motors, particularly brushless ones, are used extensively in robotics. These motors have higher efficiency and longer lifespan due to the lack of brushes, reducing maintenance needs. Automation systems with motor-driven robots enhance productivity, performing repetitive tasks with high precision and consistency.

Using motors with advanced electronic controls can further optimize performance. This plays a pivotal role in maintaining steady production rates and reducing factory downtime. Electricity and magnetic fields drive these motors, making them critical components that ensure that your manufacturing operations run smoothly.

Machine Tools and Precision Equipment

In machine tools and precision equipment, motors are key to achieving the high accuracy and precise movements required. They power lathes, milling machines, and other equipment that need exact control over speed and position.

Brushless motors are often preferred here as well, given their excellent performance and low maintenance needs. The consistency they offer is essential for maintaining the quality of manufactured products.

Precision equipment often uses motors with magnetic field controls for fine-tuning operations. This results in improved performance and reduced wear, prolonging the lifespan of the tools. Using the right motors in your machine tools ensures that your production is not just fast, but also incredibly accurate.

Types of Motors and Their Applications

Motors come in various types, each designed for specific tasks and industries. Here’s a closer look at the main types of motors and how they’re typically used.

Alternating Current (AC) Motors

AC Motors are widely used in industries because they’re efficient and easy to control. You’ll find induction motors, with squirrel cage induction motors being the most common, in everything from household appliances to conveyor belts. Click here to see some household batteries. Synchronous motors are another type, offering precision and reliability in manufacturing and processing industries.

Benefits:

- Efficient and versatile

- Low maintenance

Common Applications:

- Home appliances

- Industrial conveyors

- Process control

Direct Current (DC) Motors

DC Motors include brushed DC motors, shunt motors, series motors, and compound motors. Brushed DC motors are often used where speed control is important. Such motors are also used in golf course sprinklers. Learn more golf courses here. Shunt motors provide consistent speed, while series motors offer high starting torque. Compound motors combine features of both shunt and series motors.

Benefits:

- Excellent speed control

- High torque

Common Applications:

- Electric cars

- Elevators

- Cranes

Specialized Motors

Specialized Motors cater to niche applications. Servo motors are crucial in robotics and CNC machinery due to their precise control. Stepper motors are used in printers, 3D printers, and some remote asset monitoring devices for accurate positioning. Permanent magnet motors are efficient and compact, making them ideal for modern-day gadgets. Explosion-proof motors are designed for hazardous environments like oil and gas industries.

Benefits:

- Precise control

- Safe operation in specific conditions

Common Applications:

- Robotics

- Printing and imaging

- Hazardous environments

Motor Performance and Maintenance

Focusing on motor performance and maintenance ensures reliability and efficiency, reducing costs and downtime. Emerging techniques and technologies enable better optimization and predictive maintenance.

Optimizing Efficiency and Reliability

To keep motors running efficiently, using Variable Frequency Drives (VFDs) can be crucial. VFDs help control the speed and torque of the motor, improving energy efficiency.

Electromagnetic induction is another key factor. Ensuring proper operation can reduce electricity usage and enhance performance. Regular inspections and cleaning can help avoid damaging debris buildup.

Sensors play a vital role in monitoring motor performance. By tracking temperature, vibrations, and other critical parameters, you can predict potential issues before they cause significant downtime. This predictive maintenance approach helps maintain reliability and extends motor lifespan.

Innovations in Maintenance Techniques

New maintenance techniques focus on minimizing downtime and reducing costs. Predictive maintenance uses sensors and data analytics to foresee failures, allowing for repairs before issues become severe. This proactive approach can significantly cut maintenance costs and time.

Automated systems are another innovation that improves motor maintenance. These systems can autonomously inspect motors, detecting potential problems early on.

Ease of maintenance is also enhanced by modular designs. These enable faster part replacements, reducing the motor’s downtime for repairs. Regular online monitoring tools allow real-time performance tracking, ensuring motors run efficiently and reliably.

Advanced Applications of Motors

Motors today power numerous advanced applications across different industries. From precise automation systems to the everyday devices you rely on, motors are integral to modern life.

Automation and Control Systems

Motors play a crucial role in automation and control systems. Robotics, for instance, rely on electric motors for precise movements. Sensors and electronic controls help in positioning and operation.

- Automation systems benefit from motors.

- Elevators use motors for smooth and controlled movements.

- Power electronics and timers improve motor efficiency.

Automotive and Transportation

Motors are vital in the automotive and transportation sectors. Modern automobiles use electric drives for hybrid and electric vehicles. These drives improve energy efficiency and reduce emissions.

Household and Commercial Devices

Motors are essential in household and commercial devices. You encounter them daily, from fans to drills. Intelligence and sensors in these devices allow for smart operation and energy savings.

- Household appliances use motors for varied tasks.

- Commercial devices rely on motors for efficiency.

- Motors in electronic devices ensure reliable performance.

Published by: Holy Minoza